Container-glass recycling

"Close cycles with us! For the highest level of environmental protection and sustainability!"

Recycling of our constant companion

Had you known: On average, every German citizen produces in excess of 20 kilograms of waste from disposable glass every year.

We are aware of our responsibility and focus on sustainability and environmental protection! After all, only responsible use of resources will give new generations a future. Container glass in particular is a recyclable material that can be reintroduced into the economic cycle without any limits. Old cullet can be turned into new glass. The primary raw materials used in glass production, such as sand, soda ash, and lime, are considered virtually unlimited. Mining, transport, and processing cause a high expenditure of energy and emissions of CO2, however. Use of 10% of our processed cullet saves 3% energy and 5% CO2 in glass production.

Contact us quickly and easily via our inquiry form and receive a non-binding offer.

Container glass recycling – efficiency with the highest quality

We are one of the market leaders in the field of container glass recycling across Europe. We offer the glass manufacturing industry best cullet quality. This is, after all, the only way to ensure highest possible recyclability in the glass melt. Years ago, we developed one of today’s most advanced methods (X-ray fluorescence analysis) for separation of impurities in cooperation with US researchers. It has become indispensable in international cullet processing. We are constantly working to incorporate new findings and research results into our technical processing procedures. This enables us to achieve the best possible result in terms of purity, fines content and colour grading. Every year, more than 1 million tons of cullet can be returned to the material cycle by recycling container and flat glass by type.

Demand-driven collection options

We are there wherever you need us as a partner of dual systems, municipalities, industry, and commerce! In addition to container placement, we ensure regular collection or just-in-time pick-ups. Of course, we also guarantee complete documentation of the recycled glass quantities. Our staff will be happy to advise you, on individual glass detection options at your site as well.

Your demand – Our promise

We can produce clean recyclates free of impurities from the collected waste glass; it will be perfectly prepared for reuse in melting applications. In light of the individual specifications of glassworks and the glass processing industry, our products will be clean of CSP, FE, and non-ferrous metals as well as glass ceramics, lead-containing glasses, and organic substances after treatment.

Custom grain sizes to match your needs can be provided in addition to the guaranteed purity. We will happily take care of the entire logistics process for you in that area as well, to ensure on-time delivery and supply. We place the greatest importance on a cooperative business relationship. Therefore, not only our competent office and field staff but our entire quality management team will be available to you on site as a contact.

Click here for our glass recycling brochure.

Proper collection makes the difference

Only proper sorting by type and colour generally guarantees efficient reprocessing results. The less contaminated the glass arrives at our plants – the more efficient will recycling be. This is how we close cycles! Download the infographic now!

Flat-glass recycling

"Glass can be recycled any number of times without losing quality. It is crucial to separate and process the different types of waste glass, such as float glass, laminated glass, or insulating glass, by type."

Responsible handling of raw materials

More than 1 million tons of processed flat and container glass per year makes us a leading recycling company in Europe. 100 years of experience and more than 650 employees allow us to enable reuse of high-quality processed cullet as a secondary raw material in the various glass industries and melting applications at 12 glass sites in Germany and abroad.

Contact us quickly and easily via our inquiry form and receive a non-binding offer.

Flat glass collection – it’s your decision

In order to achieve the best possible processing results, the various types of glass waste must be collected in as pure a form as possible. We offer you individual container solutions for this purpose: from the 1.1 m³ transfer containers, 5-10 m³ large skip containers to the 15-30 m³ large roll-off containers. Your individual needs, as well as the quantity and type of glass waste generated, are decisive here. Collection of float glass, laminated glass, windshields and insulating glass, as well as mixed fractions of different glasses, is, of course possible.

In addition, we also accept windows with PVC frames as part of our Rewindo partnership. We will be happy to advise you personally on the disposal solution that best suits you and your needs! Feel free to contact us!

Shared responsibility

We achieve a consistent reduction of CO2 emissions, as well as a responsible use of available resources, together by collecting and recycling your glass waste.

However, traders are already subject to regulations on the separate collection of waste in this respect! For example, the commercial waste ordinance (Gewerbeabfallverordnung) stipulates that waste such as paper, wood, glass, and metals must be separated at the point of generation. This is the only way to ensure that the waste is recycled to the highest possible quality. We will support you – of course also on site – with an optimised disposal solution for you, as well as with the officially required disposal certificates.

Highest quality standards

The requirements of the glassworks to purity of the prepared cullet are very high. Even small amounts of impurities may lead to enclosures in the glass or discolouration. The float glass tank will be damaged in the most extreme case.

We use cutting-edge processing technology such as X-ray fluorescence analysis in order to meet the strict glassworks specifications if any non-glass materials end up in the collection container after all. We played a major role in development of this technique, which is now used worldwide. The innovative processing steps allow removal of CSP (ceramic-stone-porcelain), FE metals, and non-ferrous metals, as well as glass ceramics, lead-containing glasses, and organic substances from the collected glass waste. As a result, our recyclates can be used in virtually any melting application to add value.

Click here for our glass recycling brochure.

Working together as partners

We offer you an all-round carefree package with our comprehensive range of services, from reliable disposal logistics and container rental to personal consulting and on-site support, to delivery of a high-quality glass recyclate. Our services include complete documentation and submission of evidence. Close cycles with us!

Photovoltaics - testing for reuse & recycling

"New approaches are required to recover rare and valuable raw materials from discarded photovoltaic modules. We are rising to this challenge."

Holistic end-of-life concepts

This type of power generation has shown large growth rates throughout Europe since the turn of the millennium. The plants can make an important contribution to climate protection by clean energy generation for approximately two decades. We consider it our duty to ensure sustainability of silicon-based photovoltaic modules beyond their period of use. As a responsible recycling company, we ensure legally compliant disposal of PV modules through comprehensive testing for reuse and/or recycling - including recycling certificates. From individual PV modules to complete solar parks: we offer module manufacturers, EPCs, solar park operators, installers, businesses, dealers and collection systems holistic, economical end-of-life concepts from a single source.

Contact us quickly and easily via our inquiry form and receive a non-binding offer.

Environmentally sound collection

Two main challenges arise with regard to the end of the product life cycle when photovoltaic modules have reached the end of their service life: Legally compliant collection as well as sorted return of the valuable module components. We dedicate ourselves to this task with great commitment and the highest level of professional know-how based on more than fifteen years of experience in photovoltaics recycling. At Germany's first pure PV recycling site - Münster - the PV modules undergo testing for reuse and/or recycling. In addition to Münster, there are four further ElektroG-certified sites where we accept all types of silicon-based photovoltaic modules: Torgau, Osterweddingen, Marienfeld and Burgbernheim.

Testing for reuse

The majority of installed PV modules are still intact after more than 10 years of use, albeit with significantly reduced performance. Therefore, in the case of an economic solar park repowering, for example, the reuse route is preferable to recycling in order to conserve resources.

As the first part of our individually tailored EOL concepts, we guarantee our customers a comprehensive and reliable testing for reuse of their optically undamaged PV modules. In addition to legal compliance, the economic incentive is convincing, as is the receipt of a test report for each tested module. In addition, depending on the recycling route, corresponding recycling certificates are issued, which certify our customers a professional recycling and release them from any legal obligations.

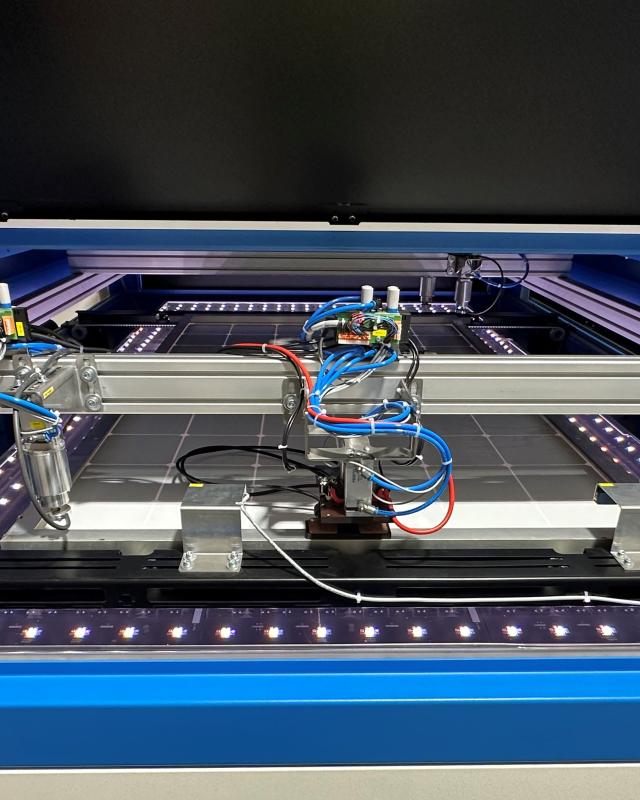

Our testing process

After visual inspection of each individual module, undamaged modules are subjected to comprehensive technical testing using various test methods. The test includes a power measurement with TÜV-certified flasher (determination of residual module power), an electroluminescence test to detect and evaluate microcracks in the solar cells and further tests to ensure electrical safety (diode test, HiPot test, grounding test). Depending on the test result, the modules are then reused as second-life modules or also recycled. In this way, we offer commercial customers in particular, such as module manufacturers and solar park operators of all sizes, a convenient, economical and legally compliant disposal solution.

Highest standards in reprocessing

Highly specialised solutions are required to ensure that all components of a photovoltaic module are separated by type. We rise to the challenge of efficiently separating the materials that are firmly bonded together in the module. As a certified primary treatment facility, we ensure best results in recycling of photovoltaic modules in cooperation with reliable partners. Preparation takes place in several steps in this process to ensure compliance with the highest quality standards. Shredding follows on primary treatment; the materials are prepared and separated for return to the recyclable material cycle in the main process step.

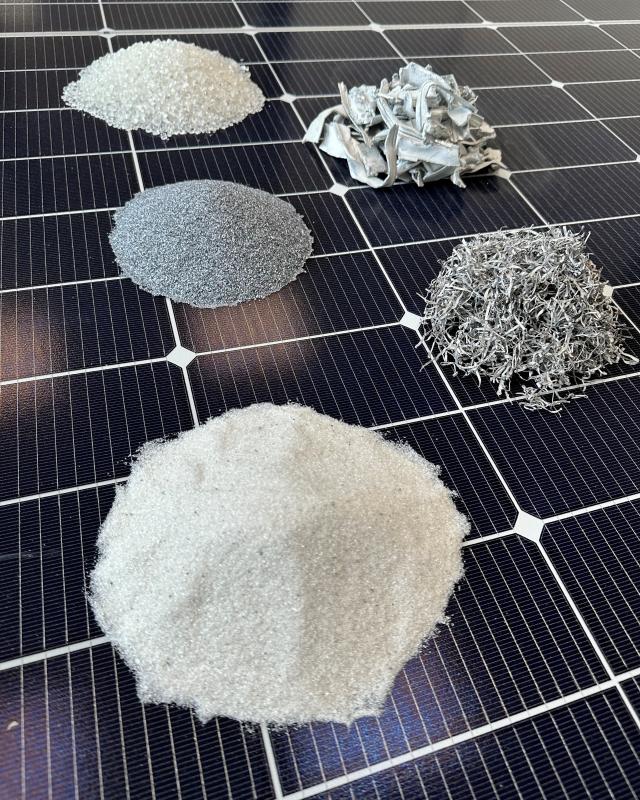

Highest quality recyclates

The main component of PV modules is glass. It is the main secondary raw material recovered. Other materials, such as aluminium, will also be optimally recycled and returned to high-quality applications. Continuous further development of the recycling processes and cutting-edge sorting techniques allow us to meet the high demands placed on the secondary raw materials obtained. Our end products are glass (fine grain), silicon, glass (coarse grain), busbars (tinned copper) and aluminum. With us you close the loop!

Efficient. Resource-saving. Environmentally friendly.

As an experienced recycling company, we meet the challenge of an environmentally friendly collection of end-of-life PV modules and their exploitation. In doing so, we attach great importance to the best possible compliance with the waste hierarchy - first reuse, then recycling. Only when reuse is not possible do we pursue the recycling of the valuable components contained in the PV modules. Expertise and years of experience as well as cutting-edge processing facilities and cooperation with reliable partners ensure best results. We are certified to ElektroG in three locations in Germany: Münster, Torgau and Osterweddingen and accept all types of silicon-based PV modules. We also take care of the quantity reports for you, and you will receive the corresponding recycling certificates.

Click here for our PV recycling brochure.

Your disposal solution – Reiling

A competent and cooperative partnership is very important to us. Therefore, our employees will also be available to you on site with their expertise as contacts across the field of professional disposal and documentation. We keep on developing our high standards to meet future requirements. We are also actively involved in various research projects and cooperate with partners to keep improving our reprocessing methods. This way, we will be able to stay your strong and reliable partner in photovoltaics recycling in future as well!

Revitro

"We think along new paths. After all, the possible uses of our high-quality granules have no creative limits!"

Glass recycling

Every year, Reiling returns over 1 million tons of used glass to the economic cycle by recycling container and flat glass by type. While the typical use is reproduction of the original product, Reiling creatively and boldly goes looking for additional, new applications: The conventional "From old to new" is supplemented by "From old to different". The "Revitro" product range is the best example of successful up-cycling.

Revitro – granulate insert rethought

Reiling represents best cullet quality; cutting-edge processes achieve best results in terms of purity, fines content – and, first and foremost, colour purity. The resulting granulate opens up recycling options that go far beyond the usual ideas of glass recycling: from decorative use in gardens and landscaping to eye-catching trade show structures.

DECORATIVELY DIFFERENT

Whether a garden bed border or green barefoot walkway in red, a blue design for roof surfaces, or accentuating bedding in asphalts, poured floors, or wall coatings: there are no limits to the applications of our granules with their diverse colour options. Decorative, individual, unique: Creative users will recognise the special nature of durable colours. Targeted use of the valuable material glass will make them stand out from common offers. Unlike conventional bulk materials such as gravel or chippings, Revitro granules are a recycled product that does not consume any natural resources in the process.

Reiling has added glass chunks to its range, supplementing the granules. These are characterised by a much greater fractions, which makes them ideal for use in gabion baskets that are particularly effective as property boundaries, retaining walls or individual objects. The glass chunks are also available in different colours and permit interesting lighting effects and additional design options due to the transparency of the material.

Are you interested now? We will gladly advise you on the various application options. Contact us!

Click here for our Revitro brochure (German only).

Our revitro varieties

Revitro granules and glass chunks come in a variety of fascinating colours and can be used in many different ways!

Some colours and grains are also available by default on short notice. Since our products are recycled materials, however, we always depend on incoming raw material. Delivery times may be longer, depending on the order quantity.

It is always worth asking, though! Also ask about unusual colours, as our range always contains special colours as well.

5094 - verde scuro - dark green

5097 - bianco - white - transparent

5100 - sepia - dark brown

5118 - aqua - turquoise

5108 - royal - dark blue

5095 - verde - pastel green

5106 - azure - light blue

5231 - reflex doblo - mirror double sided

5125 - sasso - ambra - 50-150 mm

5126 - sasso royal - dark blue - 50-150 mm

5188 - sasso aqua - turquoise - 60-110 mm

5189 - sasso aqua - tturquoise 100-180 mm

5191 - sasso crystal - clear - 60-110 mm

5196 - sasso sapphire - sapphirer blue - 50-150 mm

5250 - sasso natico - ocean blue - 50-150 mm

What colour are you looking for?

Some colours and grains are also available by default on short notice. Since our products are recycled materials, however, we always depend on incoming raw material. Delivery times may be longer, depending on the order quantity. Also ask about unusual colours, as our range always contains special colours as well.

Upcycling with Revitro: We close cycles anew – and differently!

Find a list of our varieties here!

PET Recycling

“We practice sustainability! We support our customers with tailored solutions in PET recycling.“

PET Recycling

Lightweight and extremely resistant: About two-thirds of all CSD beverages and nearly half of all mineral waters are filled in PET bottles around the world. However, efficient recycling to the highest standards is necessary to ensure responsible use of resources.

Contact us quickly and easily via our inquiry form and receive a non-binding offer. Our certificates including specifications can be found here.

A lightweight, heavy in the making – PET

Rely on an all-round service that is unparalleled anywhere in Germany with us: PET recycling with Reiling. We ensure the cycle for proper recycling from collection to processing to a high degree of purity in the provision of recyclate. This makes an important contribution to ensuring that the quantities of used PET bottles do not have to be diverted to waste incineration or refuse-derived fuel plants. Up to 75,000 metric tons of the lightweight and stable PET disposable containers per year are processed at the Dekra-certified Reiling plant in Hamm; 2020 saw the new addition of a plant in Burgbernheim, central Franconia, with a capacity of around 30,000 metric tons per year.

Demand-driven collection options

Efficient recycling starts when the consumer disposes of a PET bottle. We provide comprehensive and individual support to food and bottling companies for the collection of PET bottles and offer a choice of different models: From full service to do-it-yourself! Skips in various sizes, PET presses, or mobile briquetting presses can be used, as can self-disposal systems and stand-alone solutions in compliance with the packaging regulations. Pick-up on demand is also possible, of course! We support you based on your needs and will go looking for a bespoke solution for you.

Contact us – We are happy to coordinate an appointment on site.

Highest standards in reprocessing

Our technical facilities meet the latest standards and guarantee efficient treatment in a multi-stage process. This ensures high grade purity in our recyclate, making the reprocessed polymer material ideal for a wide range of new applications. We deliver the majority of the end products to the customer in BigBags. Silo delivery by truck is also possible for some products, however. It eliminates handling of BigBags and pallets and the corresponding waste. This is particularly important if the customer processes large quantities of flakes.

Tested quality

Our internal quality management along the process of reprocessing ensures high quality in the final product. In addition to random sampling, Reiling relies on laboratory analysis to ensure high-purity PET pellets from the washed flakes. Each BigBag and each silo delivery is also subjected to a precise quality control before the recyclate is delivered for further processing. The test checks for bulk density, off-colour and adhesive residues, as well as for impurities or foreign plastics, particle size distribution and any residual moisture.

Click here for our PET recycling brochure (German only).

Starting a new life cycle

Reiling’s PET recycling ensures that the recyclate is sorted by type and to form the basis of a wide range of uses for the recovered recyclate. In addition to blending in the production of new PET bottles, the granules are also used in the manufacture of polyester fibres as well as in film applications or packaging tapes.

Reiling – We close cycles!

Wood recycling

“We all need to use the natural resource wood responsibly, to protect our forests and the climate by extension!”

More than just waste: sustainable utilisation of waste wood

From dilapidated hunter fences to discarded euro pallets: Once processed wood has served its purpose, it often represents nothing more than waste in many eyes. Reiling, on the other hand, sees waste wood as a valuable secondary raw material in the particleboard industry and an energy source for power plants. Even though wood is a renewable raw material, responsible use of this natural product has become more important than ever before in the world we live in today. This is why we close important cycles in wood recycling in the name of sustainability!

Contact us quickly and easily via our inquiry form and receive a non-binding offer.

Individual and customised for you: Waste wood collection, container provision and recycling with Reiling

From untreated scrap wood such as wood waste or disposable pallets (Cat. A I) to particularly strongly contaminated scrap wood such as railroad sleepers or rustic fences (Cat. A IV): Reiling helps you dispose of your waste wood and prepares it for various uses by innovative techniques and the strictest controls. Our waste wood comes from a variety of sources; from industry to collections such as bulky waste, to construction and removal companies as well as private households. For example, you can dispose of the following wood waste with us:

- Ceiling panels

- Interior doors

- Window wood

- Fencing

- Wooden furniture, e.g. wardrobe / chest of drawers

- Roof battens

- Wooden pallets, crates

You can find a complete overview here.

We convince our partners with individual and customised service: Collection/disposal by the Reiling fleet can be offered, as can provision of corresponding collection containers. We offer containers in various sizes - in addition to large collection containers between 40 and 54 m3, we also have small containers (7 - 10 m3) to meet your needs and space requirements. Of course, we will collect flexibly on call.

Our 24-hour collection point is open daily ( workdays) for commercial quantities. Private deliveries are accepted Monday to Friday from 08.00 am to 04.00 pm.

Care and expertise for safe reprocessing

We sort and remove foreign materials such as paper, plastic, and metal from around 60,000 tons of waste wood every year and then shred it. The material is stored in covered hoppers to minimise residual moisture. The suitability of scrap wood also always depends on the pollutant burden from the varnishes and treatments of the wood at hand. We offer security by careful outgoing inspections and a close-meshed network of sampling for the laboratory.

The final products: From chipboard to energy carrier

Wood chips for the particleboard industry: In addition to chipboard for normal household use, chipboard for the furniture industry and specific floor coverings is also made of our waste wood. Reiling ensures sustainability among its customers as well: All partners are FSC and PEFC certified; the coated DecoBoards are certified with the Blue Angel as well.

Wood chips for combustion: We supply power plants as well as biomass cogeneration plants with wood chips for combustion, contributing to generation of climate-neutral energy (electricity and heat).

G 30 chips for heating and small-scale systems

A good alternative to conventional forest and sawmill chips, our G 30 chips are made of entirely untreated recycled wood; with a particle size of up to 30 mm and a moisture/water content of less than 20 percent. They can often also be burned in woodchip stoves or pellet heating systems. Talk to the respective manufacturer about this. Transport or collection takes place smoothly thanks to the specially developed special blow-in containers.

Click here for our wood recycling brochure (German only).

Care & expertise

We will gladly deliver the desired fractions – or keep them at hand for you in our warehouse! Just talk to us.