Competence centre PV recycling in Münster - Opening of Germany's first Reiling PV recycling site

Münster, 6 June 2023 - With the opening of Germany's first Reiling PV recycling site, we are preparing for the recycling of the expected future masses of discarded (EOL) PV modules. The focus of the new PV recycling competence centre in Münster is: collection, testing for reuse and recycling of silicon-based PV modules. The multi-million investment in the site with a new testing line and an innovative, specially developed recycling plant represents a milestone with regard to the recycling of PV modules on an industrial scale. By bundling the testing and recycling activities in Münster, process flows are to be optimised and recycling capacity significantly increased. "With an expected recycling capacity of 50,000 tonnes of PV modules per year, we are well prepared for the next years," reports our Managing Director of Reiling PV-Recycling GmbH & Co. KG Tom Reiling. Last year, our company already recycled close to 6,000 tonnes of PV modules - however, by 2030, 400,000 tonnes of disused PV modules are expected to be disposed of cumulatively in Germany (IRENA, 2016). In addition, an increase in active solar park repowerings and a further rise in demand for second-life modules on the second-hand market are expected. Besides, in addition to the day-to-day business, the PV recycling site will also be used as a research and development site to further improve the process and the quality of the end products, such as the glass.

Testing for reuse

At the beginning of this year, our test line was already installed at the Münster site. This is because not all modules are defective after their first useful life and must necessarily be recycled. In some cases, such as active solar park repowering, a "second life" is possible and resources can be conserved. Therefore, we test optically still intact modules with regard to performance and electrical safety and will offer them on the second-hand market in the future. If the test result is negative, the modules can be transferred directly to recycling.

PV recycling

Our new and specially developed PV recycling plant (technology application and process sequence) is based on our research and development results of the last 15 years. Previously, the PV modules were processed at the glass recycling sites of the Reiling Group. Now these sites still function to accept the discarded PV modules.

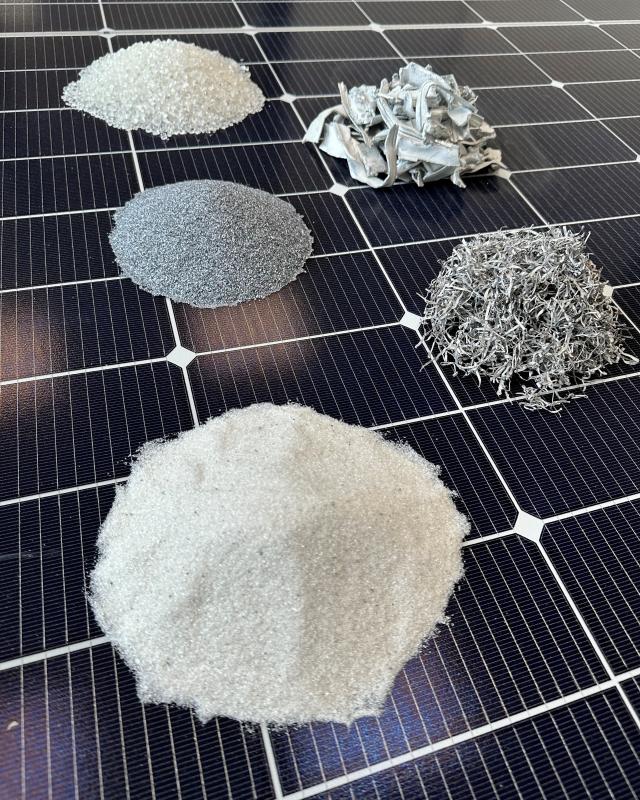

In the first step of our mechanical recycling process, the entire PV module is shredded. The materials are then separated using various sorting technologies. In the process, end products such as glass, aluminium, conductors (e.g. bus bars) as well as a cable and foil fraction can be recovered. Except for the foil (thermal recycling), all recovered secondary raw materials can be used in industry for new products.

In addition, we are also researching with high intensity on the recovery of silicon and silver. In a joint research project with Fraunhofer CSP, we succeeded in developing a promising recycling process for recovering the silicon as well as precious metals such as silver. Thus, we have already recycled these materials on a tonne scale and want to expand the process to industrial scale in Münster in the future.

Our end products after the recycling process

We receive glass (fine grain; f.l.), silicon (m.l.), glass (coarse grain; b.l.), conductors (f.r.) and aluminium (b.r.).

You can find more information on our photovoltaics business unit here.