TOGETHER WITH THE TWO OTHER PARTNER COMPANIES SAINT-GOBAIN GLASS AND SAINT-GOBAIN SEKURIT OF THE CAR MANUFACTURER AUDI, WE ARE TAKING ON THE CHALLENGE OF ESTABLISHING A CLOSED MATERIAL CYCLE FOR NON-REPAIRABLE CAR GLASS AS PART OF A ONE-YEAR PILOT PROJECT AND ARE THUS DOING PIONEERING WORK.

This is because irreparable windscreens are to be turned into a valuable material for the series production of windscreens - a unique process to date. Currently, the glass recyclate recovered from damaged windscreens is returned to low-value applications, i.e. used for the production of insulating material or hollow glass.

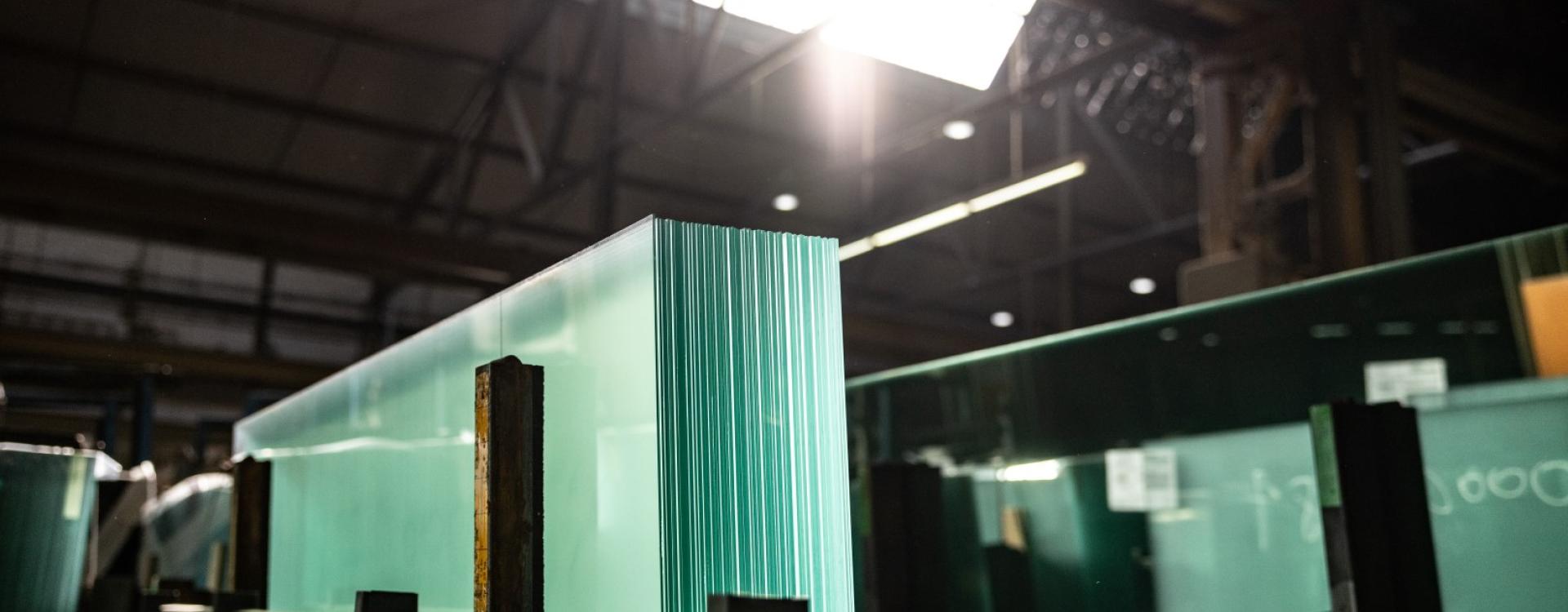

And this is exactly where the policy project comes in: namely, to recycle the damaged glass back to its original quality for car windscreens. As a recycling specialist for flat glass, we rise to the challenge and take on this first step in the multi-stage process to create a new pane - the crushing, separation and processing of the old glass handed over to us.

In order to be able to produce a high-quality, recyclable recyclate from the old glass, we use modern and efficient plants. Substances foreign to glass, such as PVB plastic layers (polyvinyl butyral) in the glass, window frames, metals and wires are meticulously sorted out. The so-called rejection is carried out by means of magnets, non-ferrous metal separators, suction systems and electro-optical sorting units.

The recovered glass granulate is then transferred to the second partner company Saint-Gobain Glass for the production of flat glass. In the further process, the sister company Saint-Gobain Sekurit produces the new automotive glazing. The reprocessing of the damaged glass means that less energy and raw materials have to be used overall for the production of panes - after all, the use of reprocessed material makes it possible to reduce the need for primary materials such as quartz sand.

If this pilot is successful, the windscreens produced in this way will be used for the models in the Audi Q4 e-tron series in the future. We are very much looking forward to working together on this exciting and pioneering pilot project for a more sustainable future!